ئەڭ كۆپ سېتىلىدىغان رازىمەنلىك كاپالىتى ئەلا سۈپەتلىك يۇقىرى ساپلىقتىكى بىسفېنول ئاف

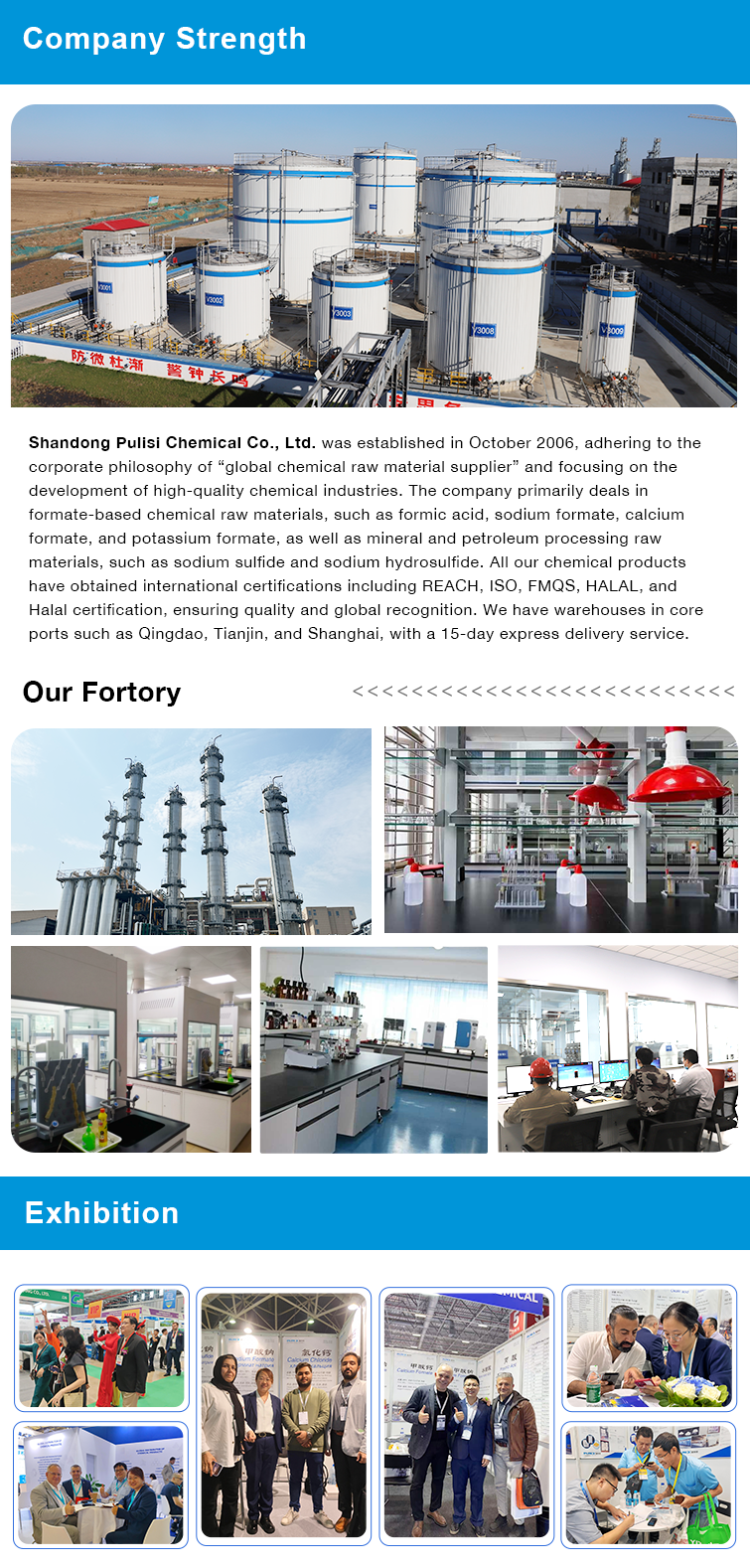

شىركىتىمىز «مەھسۇلات سۈپىتى كارخانىنىڭ داۋاملىق ياشىشىنىڭ ئاساسى؛ خېرىدارلارنىڭ رازىلىقى كارخانىنىڭ باشلىنىش نۇقتىسى ۋە ئاخىرى؛ ئۈزلۈكسىز ياخشىلاش خىزمەتچىلەرنىڭ مەڭگۈلۈك ئىزدىنىشى» دېگەن سۈپەت سىياسىتىدە چىڭ تۇرىدۇ ۋە ئەڭ كۆپ سېتىلىدىغان، رازىمەنلىك كاپالىتىگە ئىگە ئەلا سۈپەتلىك يۇقىرى ساپلىقتىكى بىسفېنول ئاففېنول ئۈچۈن «ئابروي بىرىنچى، خېرىدار بىرىنچى» دېگەن ئىزچىل مەقسەتنى قوللىنىدۇ. بىز دۇنيانىڭ ھەرقايسى جايلىرىدىكى خېرىدارلىرىمىز بىلەن بىرلىكتە ئۆسۈپ يېتىلىۋاتقانلىقىمىزغا چىن دىلىمىزدىن ئۈمىد قىلىمىز.

شىركىتىمىز «مەھسۇلات سۈپىتى كارخانىنىڭ داۋاملىق ياشىشىنىڭ ئاساسى؛ خېرىدارلارنىڭ رازىلىقى كارخانىنىڭ باشلىنىش نۇقتىسى ۋە ئاخىرى؛ ئۈزلۈكسىز ياخشىلاش خىزمەتچىلەرنىڭ مەڭگۈلۈك ئىزدىنىشى» دېگەن سۈپەت سىياسىتى ۋە «ئابروي بىرىنچى، خېرىدار بىرىنچى» دېگەن ئىزچىل مەقسىتىدە چىڭ تۇرىدۇ. تاۋارلار ئاسىيا، ئوتتۇرا شەرق، ياۋروپا ۋە گېرمانىيە بازارلىرىغا ئېكسپورت قىلىندى. شىركىتىمىز بازارلارغا ماسلىشىش ئۈچۈن مەھسۇلاتلارنىڭ ئىقتىدارى ۋە بىخەتەرلىكىنى ئۈزلۈكسىز يېڭىلاپ، مۇقىم سۈپەت ۋە سەمىمىي مۇلازىمەت جەھەتتە ئالدىنقى قاتاردا تۇرۇشقا تىرىشىدۇ. ئەگەر سىز شىركىتىمىز بىلەن سودا قىلىش شەرىپىگە ئېرىشسىڭىز، بىز چوقۇم جۇڭگودىكى سودىڭىزنى قوللاش ئۈچۈن قولىمىزدىن كېلىشىچە تىرىشىمىز.

بىسفېنول A نىڭ ساقلاش شارائىتى «بۇزۇلۇشنىڭ ئالدىنى ئېلىش، بىخەتەرلىككە كاپالەتلىك قىلىش ۋە مۇھىتقا تەسىر كۆرسىتىشتىن ساقلىنىش» قاتارلىق ئاساسىي مەقسەتلەرنى چۆرىدىگەن ھالدا بولۇشى كېرەك.

بىسفېنول A (BPA) نىڭ ئىشلىتىلىشى

بىسفېنول A (BPA) پولىكاربونات، ئېپوكسى قالدۇقى ۋە يۇقىرى تېمپېراتۇرىغا چىداملىق پولىئېستېرلارنى بىرىكتۈرۈشتە مۇھىم خام ئەشيا. ئۇ يەنە PVC مۇقىملاشتۇرغۇچى، سۇلياۋ ئوكسىدلىنىشقا قارشى تۇرغۇچى، ئۇلترا بىنەپشە نۇرنى سۈمۈرگۈچى، زەمبۇرۇغقا قارشى تۇرغۇچى قاتارلىقلار سۈپىتىدە ئىشلىتىلىدۇ.

كۆپ ئىقتىدارلىق بىرىكمە سۈپىتىدە، BPA ئېپوكسى رېشىنكىسى، پولىكاربونات، پولىئېستېر رېشىنكىسى، پولىفېنىلېن ئېفىر رېشىنكىسى ۋە پولىسۇلفون رېشىنكىسى ئىشلەپچىقىرىشتا كەڭ كۆلەمدە ئىشلىتىلىدۇ. بۇنىڭدىن باشقا، ئۇ پولىۋىنىل خىلورىد (PVC) نىڭ مۇقىملاشتۇرغۇچىسى، پلاستىكلاردىكى ئوكسىدلىنىشقا قارشى تۇرغۇچى، ئۇلترابىنەفشە نۇرنى سۈمۈرگۈچى، دېھقانچىلىق زەمبۇرۇغقا قارشى تۇرغۇچى ۋە كاۋچۇكتىكى قېرىشقا قارشى تۇرغۇچى ماددا رولىنى ئوينايدۇ.

ئۇ يەنە بوياق ۋە سىياھلاردا ئوكسىدلىنىشقا قارشى تۇرۇش ۋە پلاستىكلاشتۇرغۇچى سۈپىتىدە ئىشلىتىلىدۇ. ئورگانىك بىرىكتۈرۈشتە، BPA ئېپوكسى ۋە پولىكاربونات قالدۇقلىرىنى ئىشلەپچىقىرىشتا مۇھىم تەركىب رولىنى ئوينايدۇ، ھەمدە يۇقىرى مولېكۇلالىق سۈنئىي بىرىكمىلەرنىڭ مۇھىم خام ئەشياسى، شۇنداقلا قېرىشنىڭ ئالدىنى ئېلىش دورىلىرى، پلاستىكلاشتۇرغۇچىلار ۋە دېھقانچىلىق زەمبۇرۇغقا قارشى دورىلار سۈپىتىدە كەڭ قوللىنىلىدۇ.

1. يەتكۈزۈش ئىشەنچلىكلىكى ۋە مەشغۇلات مۇنەۋۋەرلىكى

ئاساسلىق ئالاھىدىلىكلەر:

چىڭداۋ، تيەنجىن ۋە لۇڭكوۋ پورتلىرىدىكى 1000 دىن ئارتۇق ئىستراتېگىيىلىك زاپاس ساقلاش مەركەزلىرى

مېترىك توننا زاپاس بار

زاكازلارنىڭ %68 ى 15 كۈن ئىچىدە يەتكۈزۈلدى؛ جىددىي زاكازلار تېز يوللانما ئارقىلىق ئالدىن بېكىتىلدى

قانال (%30 تېزلىنىش)

2. سۈپەت ۋە قائىدە-تۈزۈملەرگە ماسلىشىش

گۇۋاھنامىلەر:

REACH، ISO 9001 ۋە FMQS ئۆلچەملىرى بويىچە ئۈچ قېتىم گۇۋاھنامىگە ئېرىشكەن

دۇنياۋى گىگىيېنا قائىدىلىرىگە ئۇيغۇن؛ %100 تاموژنىدىن ئۆتۈش مۇۋەپپەقىيەت نىسبىتى

رۇسىيە ئىمپورتى

3. سودا بىخەتەرلىك رامكىسى

پۇل تۆلەش چارىلىرى:

ئەركىن شەرتلەر: LC (كۆرۈش/مۇددەت)، TT (%20 ئالدىن + %80 توشۇلغاندىن كېيىن)

مەخسۇس لايىھەلەر: جەنۇبىي ئامېرىكا بازارلىرى ئۈچۈن 90 كۈنلۈك LC؛ ئوتتۇرا شەرق: %30

ئامانەت + BL تۆلەم

تالاش-تارتىشنى ھەل قىلىش: بۇيرۇققا مۇناسىۋەتلىك توقۇنۇشلارغا 72 سائەتلىك جاۋاب قايتۇرۇش قائىدىسى

4. چاققان تەمىنلەش زەنجىرى ئۇل ئەسلىھەلىرى

كۆپ موداللىق لوجىستىكا تورى:

ھاۋا يولى ئارقىلىق يۈك توشۇش: تايلاندقا پروپىئون كىسلاتاسى توشۇش ئۈچۈن 3 كۈن ئىچىدە يەتكۈزۈش

تۆمۈر يول قاتنىشى: ياۋروئاسىيا كارىدورى ئارقىلىق رۇسىيەگە بارىدىغان كالتسىي فورماتى مەخسۇس يولى

ISO TANK چارىلىرى: بىۋاسىتە سۇيۇق خىمىيىلىك ماددىلارنى يەتكۈزۈش (مەسىلەن، پروپىئون كىسلاتاسى)

ھىندىستان)

ئورالمىنى ئەلالاشتۇرۇش:

Flexitank تېخنىكىسى: ئېتىلېن گلىكولنىڭ تەننەرخىنى %12 تۆۋەنلىتىش (ئەنئەنىۋى دۇمباققا سېلىشتۇرغاندا)

ئورالما)

قۇرۇلۇش دەرىجىلىك كالتسىي فورماتى/ناترىي گىدروسۇلفىد: نەملىككە چىداملىق 25 كىلوگراملىق توقۇلغان PP خالتىلار

5. خەتەرنى ئازايتىش قائىدىلىرى

باشتىن-ئاخىر كۆرۈنۈش:

كونتېينېر توشۇشنى ھەقىقىي ۋاقىتلىق GPS ئارقىلىق نازارەت قىلىش

نىشان پورتلىرىدىكى ئۈچىنچى تەرەپ تەكشۈرۈش مۇلازىمىتى (مەسىلەن، جەنۇبىي ئافرىقىغا ئاتسېتاتىك كىسلاتا توشۇش)

سېتىشتىن كېيىنكى كاپالەت:

30 كۈنلۈك سۈپەت كاپالىتى، ئالماشتۇرۇش/پۇل قايتۇرۇش ئىمكانىيىتى بىلەن

مۇزلاتقۇچلۇق كونتېينېر توشۇش ئۈچۈن ھەقسىز تېمپېراتۇرا كۆزىتىش ئەسۋابى

كونا سۇلفات كىسلاتاسى ئۇسۇلى ئارقىلىق ئىشلەپچىقىرىلغان بىسفېنول A (BPA) نىڭ سۈپىتى تۆۋەن، ھەمدە پولىكاربونات ئىشلەپچىقىرىش ئۈچۈن پولىكاربونات دەرىجىلىك بىسفېنول A BPA لازىم. بۇنىڭدىن باشقا، ئىشلەتكۈچىلەر ئېپوكسى قالدۇقلىرىنىڭ سۈپىتىگە تېخىمۇ يۇقىرى تەلەپلەرنى قويدى. شۇڭا، يۇقىرى سۈپەتلىك ئېپوكسى قالدۇقلىرىنى ئىشلەپچىقىرىش ئۈچۈن يۇقىرى سۈپەتلىك بىسفېنول A BPA لازىم.